Conditioning Technology

Reliable

Uniform Treatment

Robust Design

In order to obtain the maximum pressing results, the adequate thermal treatment of the seed is essential.

This leads to spontaneous evaporation of water within the cellular structure of the seed and reduces the seed’s surface moisture. The decisive factor for this process lies in correct design and selection of the right system, while taking procedural and qualitative aspects into consideration.

Drum-type Conditioner

Horizontal cylindrical conditioner with double jacket drum for indirect heating with saturated steam

- Intensive mixing by special agitator leading to homogenous treatment

- Agitator shaft suitable for indirect heating with saturated steam

- High drying efficiency due to immediate discharge of vapors

- Drums available in 2 sizes (1.25 m diameter and 7.5 m long or 2.0 m diameter and 9.0 m long)

- Drums of one size can be stacked upon each other (double, triple)

- Ideal for full-pressing systems and smaller pre-pressing systems

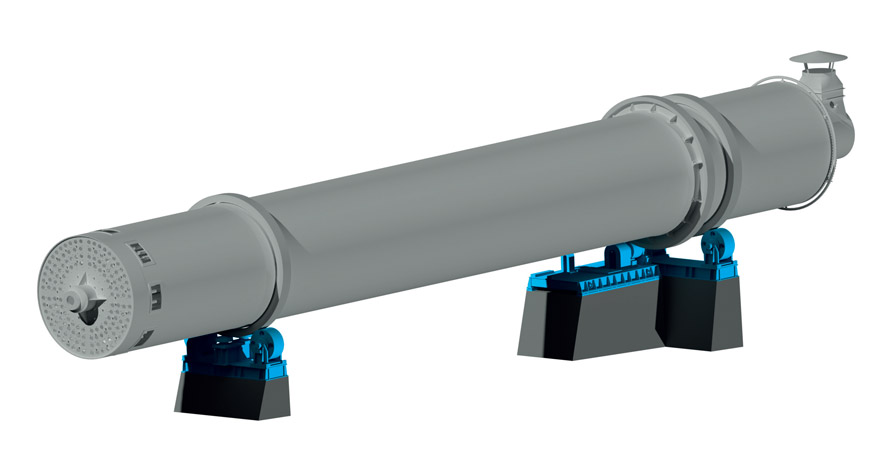

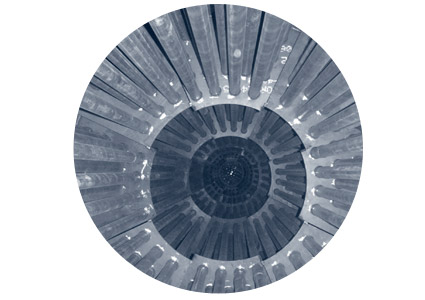

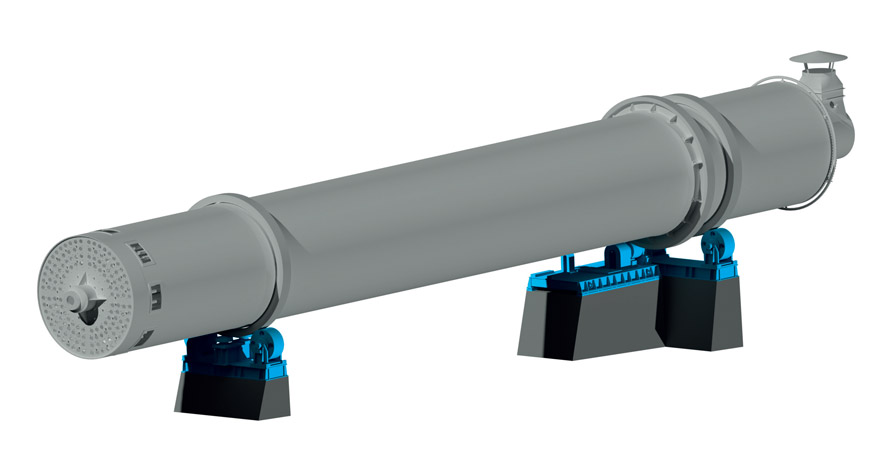

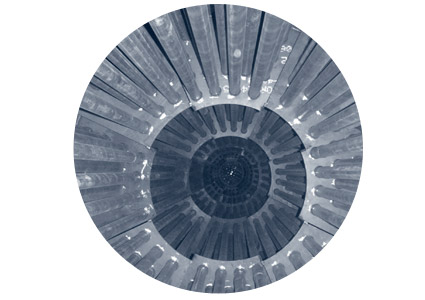

Rotary Tube Bundle Conditioner

Horizontal cylindrical conditioner with centrically – arranged steam-heated tube bundle. The complete drum rotates.

- Optimum ratio of heating surface to required space

- High drying efficiency due to immediate discharge of vapours

- Drums available with 2 standard diameters (3.0 m and 3.5 m)

- Several drum lengths available to meet customer’s requirements

- Rotation of the conditioner and individual heating tubes arranged and fixed over the entire length of the conditioner leading to homogenous treatment

- Ideal for large capacity plants